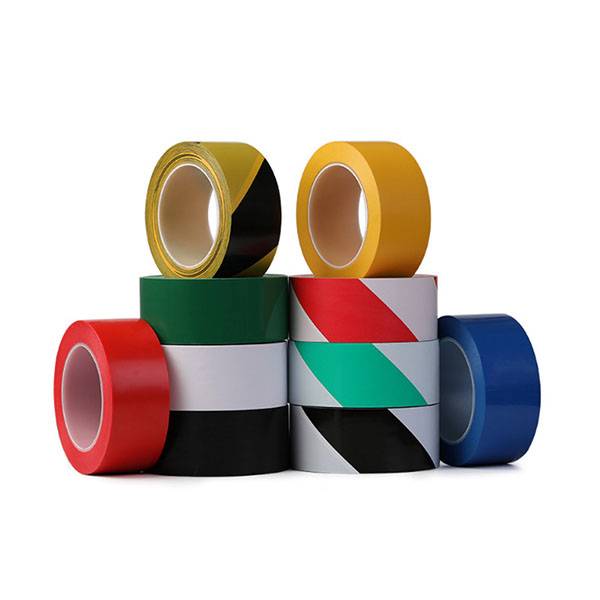

High-Quality PVC Tape with CE Certification from Reliable Factory

When I came across PVC tape, I immediately recognized its value for various industrial applications. Not only is it incredibly versatile, but it also boasts CE Certification, assuring quality and safety in its usage. As a reliable factory-manufactured product, this PVC tape meets high standards and is ideal for both electrical insulation and surface protection. I’ve used this tape in countless projects, and its strong adhesive properties never let me down. Whether you’re sealing, binding, or reinforcing, PVC tape is a go-to solution that can withstand wear and tear. Plus, sourcing from a factory ensures consistency in quality, making it a wise choice for bulk purchases. With its ease of use and efficiency, it quickly becomes a staple in any workshop or workspace. If you're seeking reliability and performance, then PVC tape is the answer you’ve been looking for!

pvc tape Application Pioneers in the Field

In the ever-evolving realm of adhesive solutions, PVC tape stands out as an essential product for various industries, given its versatility and reliability. Known for its resistance to moisture, abrasion, and chemicals, PVC tape is increasingly being adopted across applications ranging from electrical insulation to automotive assembly. As businesses seek innovative ways to streamline operations and enhance product durability, understanding the capabilities and advantages of PVC tape becomes paramount. Pioneers in the field demonstrate that innovation drives the advancement of PVC tape applications. For instance, advancements in adhesive technology have led to the development of tapes that are not only stronger but also more environmentally friendly. These innovations cater to the growing demand for sustainable industrial practices. Furthermore, the customization options available now allow for tailored solutions that meet specific needs, whether for high-temperature applications or applications requiring special colors and finishes. As global procurement professionals look for reliable and efficient solutions, PVC tape has emerged as a top choice. Its adaptability, durability, and ease of use make it an invaluable tool in various settings. Businesses aiming to enhance their manufacturing processes or improve product quality should consider integrating advanced PVC tape solutions into their operations, ensuring they stay ahead in today's competitive landscape.

PVC Tape Application Pioneers in the Field

| Application Area | Type of PVC Tape | Key Features | Common Uses |

|---|---|---|---|

| Electrical Insulation | Electrical PVC Tape | High dielectric strength, flame retardant | Wiring, cable insulation, bundling |

| Packaging | General Purpose PVC Tape | Strong adhesive, transparent | Sealing boxes, packaging |

| Automotive | Automotive PVC Tape | Weather-resistant, UV stable | Wiring harness, insulation |

| Construction | Duct PVC Tape | Water resistant, durable | Sealing ducts, HVAC installation |

| Medical | Medical PVC Tape | Hypoallergenic, sterile | Bandage securing, medical wiring |

Related Products