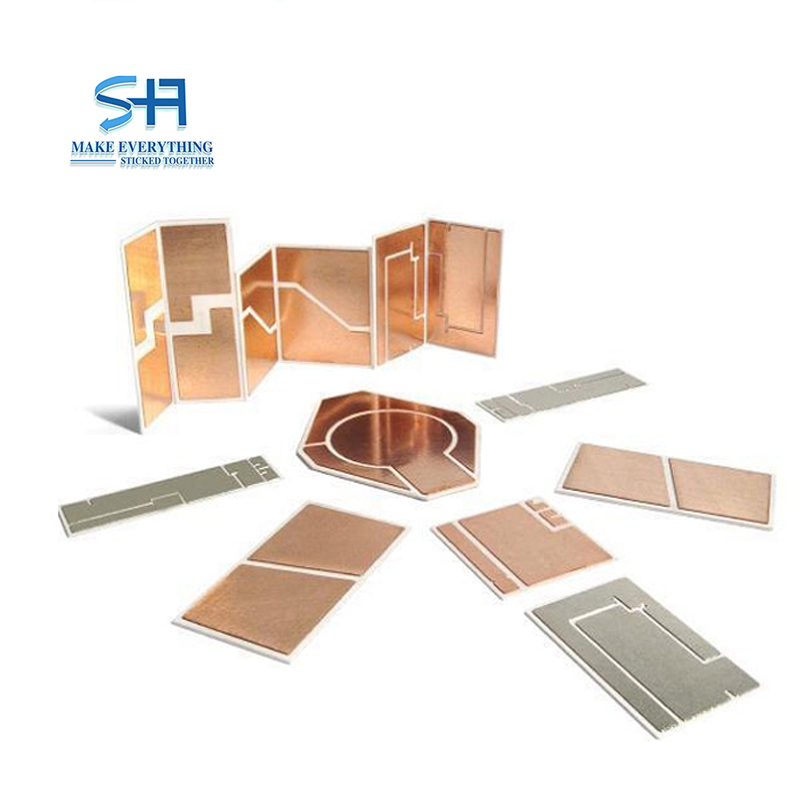

Top China Manufacturer of Copper Foil Conductive Tape for Electronics

When it comes to high-performance electrical applications, I highly recommend our Copper Foil Conductive Tape, sourced directly from trusted manufacturers in China. This tape is engineered with precision, providing excellent conductivity while being incredibly versatile for a variety of uses. Whether you're in the electronics industry or tackling DIY projects, this conductive tape ensures reliable connections and enhances signal integrity. The adhesive backing offers easy application to a range of surfaces, making it perfect for circuit repairs, shielding, and more. I find it especially useful for custom electronics and RF applications, where precision matters. By choosing our Copper Foil Conductive Tape, you're investing in quality and performance. With competitive pricing and superior durability, it truly stands out in the marketplace. If you’re in need of a reliable solution, this tape can help streamline your projects with ease and efficiency.

Copper Foil Conductive Tape Winning in 2025 From Concept to Delivery

In the rapidly evolving landscape of electronic manufacturing, copper foil conductive tape is emerging as a pivotal component, driving innovation and efficiency in 2025 and beyond. This versatile material offers exceptional conductivity, flexibility, and ease of application, making it ideal for a wide range of applications from automotive electronics to consumer gadgets. As industries worldwide seek to enhance their products' performance and reliability, the demand for high-quality copper foil conductive tape is set to soar. The journey from concept to delivery involves meticulous attention to detail and collaboration across various stages of production. The manufacturing process starts with sourcing premium raw materials, ensuring that the tape not only meets but exceeds industry standards. Once the adhesive and copper foil are carefully combined, rigorous quality control measures are put in place to guarantee that each roll of tape is uniform and ready for deployment. This commitment to excellence is vital in maintaining strong relationships with global buyers who prioritize quality in their supply chains. Looking ahead, the market for copper foil conductive tape is poised for significant growth, driven by advancements in technology and an increasing focus on sustainable practices. As manufacturers focus on reducing environmental impact, integrating eco-friendly processes and materials becomes essential. For global procurement professionals, staying informed about these trends will be crucial. Investing in reliable, high-quality conductive tape can provide a competitive edge, ensuring that products not only perform efficiently but also align with the evolving demands of consumers and regulations. Embrace the future of electronics with innovative materials that elevate performance and sustainability in your offerings.

Copper Foil Conductive Tape Winning in 2025 From Concept to Delivery

| Dimension | Description | Expected Growth (%) | Application Areas | Market Trends |

|---|---|---|---|---|

| Thickness | Range of 18µm to 35µm for different applications | 15% | Electronics, Automotive, Medical Devices | Increase in demand for lightweight materials |

| Adhesive Type | Conductive and Non-Conductive options | 20% | Smart Devices, Robotics | Growth in smart technology integration |

| Color | Copper standard, options for various colors | 10% | Consumer Electronics, Industrial Machinery | Custom colors for branding purposes |

| Width | Available in widths from 3mm to 300mm | 12% | Electrical Insulation, Shielding | Increased use in telecommunications |

| Roll Length | Standard roll lengths of 10m to 50m | 8% | Construction, DIY Projects | Rising DIY trends boosting usage |

Related Products