Wholesale Hot Melt Adhesive Applicators from Leading Manufacturers

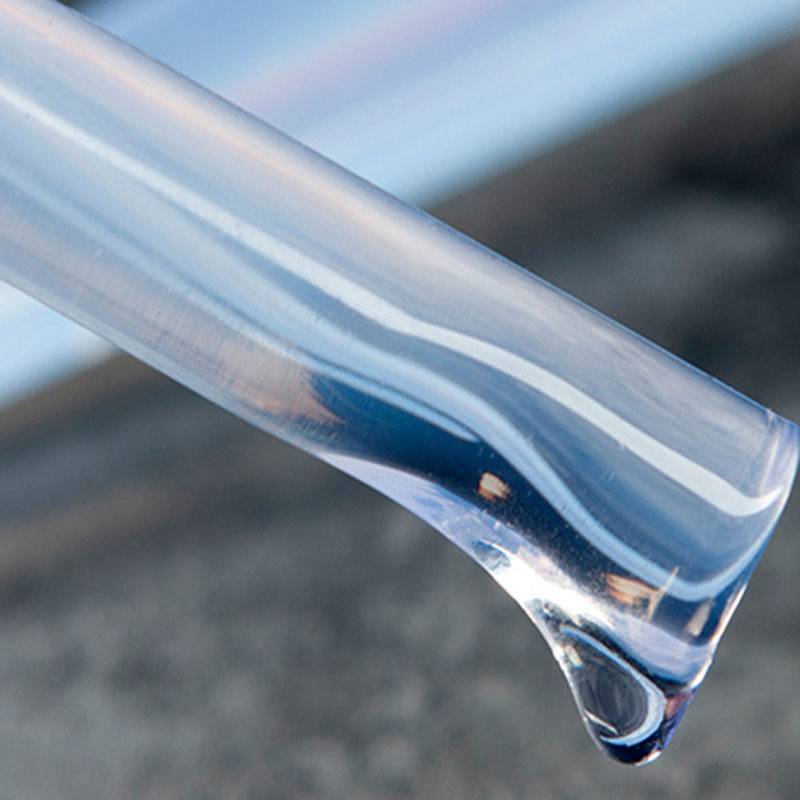

When I think about efficiency in production, the Hot Melt Adhesive Applicator comes to mind as an essential tool for my operations. This versatile equipment is perfect for manufacturers seeking reliable adhesive application without the mess. As a wholesale buyer, I appreciate the cost-effectiveness this applicator provides, allowing me to scale up operations without compromising on quality. With user-friendly features, it offers precise control and quick heating, ensuring minimal downtime during busy production runs. I find this applicator particularly useful for a wide range of applications, from packaging to assembly. Partnering with trusted manufacturers means I can rely on consistent performance and durability, which is crucial in my industry. By investing in a Hot Melt Adhesive Applicator, I'm not only boosting productivity but also enhancing overall product quality. This is a game-changer for anyone in the manufacturing space looking to improve their adhesive processes on a budget.

Hot Melt Adhesive Applicator Custom Solutions, Your End-to-End Solution

In today's fast-paced manufacturing environment, having reliable and efficient application solutions is paramount for success. Hot melt adhesive applicators offer remarkable versatility, catering to a myriad of industries including packaging, automotive, electronics, and woodworking. Custom solutions in applicator technology not only streamline production processes but also enhance product quality and durability. By tailoring these systems to specific operational requirements, businesses can achieve optimized adhesive performance, ensuring minimal downtime and maximum efficiency. Global procurement partners are increasingly recognizing the significance of investing in advanced hot melt adhesive technologies. The right applicator can significantly reduce material waste and improve application accuracy, leading to substantial cost savings. With innovations in automation and digital integration, today's applicators offer enhanced monitoring capabilities, providing real-time data that helps in decision-making and process adjustments. This forward-thinking approach not only boosts productivity but also aligns with sustainability goals by optimizing resource use. As the demand for customized adhesive solutions continues to grow, embracing the full spectrum of available technologies is crucial. From initial consultation to final implementation, a comprehensive end-to-end solution ensures that procurement partners receive not merely a product, but a strategic advantage in their operations. With expertise in developing tailored adhesive systems, businesses can seamlessly navigate the complexities of modern manufacturing and emerge as leaders in their respective markets.

Hot Melt Adhesive Applicator Custom Solutions, Your End-to-End Solution

| Application Area | Adhesive Type | Temperature Range (°C) | Nozzle Diameter (mm) | Output Rate (kg/h) | Customization Options |

|---|---|---|---|---|---|

| Packaging | Hot Melt | 180 - 200 | 4 | 10 | Yes |

| Automotive | Polyurethane | 150 - 180 | 6 | 15 | Yes |

| Furniture | EVA | 160 - 190 | 8 | 20 | Yes |

| Electronics | Ethylene Vinyl Acetate | 130 - 160 | 2 | 5 | Yes |

| Medical | Medical Grade | 150 - 175 | 3 | 8 | Yes |

Related Products