CE Certified Pipe Wrap Insulation Tape from Leading Factory Suppliers

When it comes to insulation solutions, I've found that Pipe Wrap Insulation Tape stands out for its performance and reliability. It’s designed to provide exceptional thermal insulation, which is crucial for those in industries where temperature control is key. With CE Certification, you can trust that this tape meets high safety and quality standards, ensuring it’s suitable for various applications. I source this tape from a reputable factory, emphasizing quality and durability in every roll. The adhesive is strong, making sure it sticks well, even in challenging environments. It's easy to apply, allowing for quick installations and repairs, which saves both time and money. As a B2B purchaser, you’ll appreciate how this product can enhance your operations while maintaining compliance with necessary regulations. Reinforced by my own experiences, I believe Pipe Wrap Insulation Tape is an investment worth making for efficient and effective insulation solutions.

Pipe Wrap Insulation Tape Products From Concept to Delivery

In today’s fast-paced industrial landscape, the importance of reliable insulation materials cannot be overstated. Pipe wrap insulation tape is a versatile solution designed to enhance energy efficiency and prevent heat loss in various applications. Whether for plumbing systems, HVAC installations, or even automotive enhancements, these products play a crucial role in ensuring optimal performance while reducing energy costs. From the initial concept phase to the final delivery, the manufacturing process of pipe wrap insulation tape emphasizes quality and innovation. Advanced materials and cutting-edge technology are employed to create tapes that not only resist extreme temperatures but also provide excellent adhesion and durability. With customization options available, businesses can procure insulation solutions that meet their specific requirements in terms of thickness, width, and adhesive strength, ensuring they achieve the best possible outcomes for their projects. As global demand for efficient insulation solutions rises, sourcing high-quality pipe wrap insulation tape has never been more critical. Companies looking to enhance their product offerings and ensure customer satisfaction can benefit from forming partnerships with reputable manufacturers that prioritize technical excellence and reliable delivery. By choosing the right insulation solutions, businesses can significantly contribute to energy conservation efforts, aligning with global sustainability goals while also improving their operational efficiencies.

Pipe Wrap Insulation Tape Products From Concept to Delivery

| Product Name | Material | Thickness (mm) | Temperature Range (°C) | Width (mm) | Length (m) |

|---|---|---|---|---|---|

| High-Temperature Silicone Tape | Silicone | 0.5 | -60 to 260 | 50 | 10 |

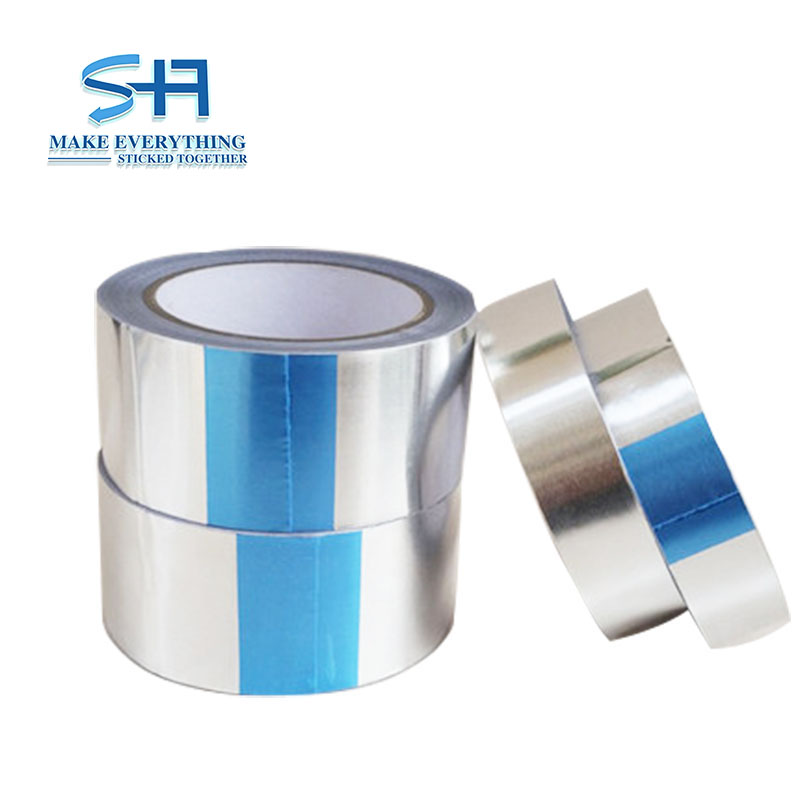

| Foil Insulation Tape | Aluminum Foil | 0.1 | -40 to 120 | 100 | 20 |

| PVC Insulation Tape | PVC | 0.15 | -10 to 80 | 25 | 15 |

| Nitrile Rubber Tape | Nitrile Rubber | 1.0 | -30 to 100 | 75 | 12 |

| Fiberglass Insulation Tape | Fiberglass | 0.8 | -50 to 550 | 100 | 25 |

Related Products