Affordable Single Sided Eva Foam Tape from Reliable Factories

When I needed a versatile solution for my packaging needs, I turned to single sided EVA foam tape. This tape stands out because it’s not only affordable but also durable. Factories and manufacturers rely on it for various applications, from cushioning fragile items to creating a secure bond on uneven surfaces. I found that it sticks well without leaving a residue, making it perfect for quick fixes or long-term projects. The foam material provides excellent shock absorption, which is crucial in shipping and manufacturing environments. Plus, its ease of use means even small operations can add it to their assembly line without hassle. Trust me, if you're aiming for reliable quality at a cheap price, this single sided EVA foam tape is your go-to solution. It’s a simple yet effective tool that enhances productivity and ensures your products reach their destination safely. Don’t miss out on this essential item for your factory or business!

Single Sided Eva Foam Tape Dominates Winning in 2025

As we look forward to 2025, the demand for single-sided EVA foam tape is set to dominate various markets worldwide. These versatile adhesive solutions offer exceptional bonding strength, making them ideal for applications across diverse industries such as automotive, electronics, construction, and packaging. Global procurement professionals are increasingly recognizing the advantages of EVA foam tape due to its excellent cushioning properties, thermal insulation, and resistance to moisture and UV light. Moreover, advancements in manufacturing technology have led to enhanced product performance, enabling EVA foam tape to meet the stringent requirements of today’s industries. With customization options available, suppliers can cater to specific needs, including varying thicknesses, widths, and adhesive strengths. This adaptability not only allows for seamless integration into various applications but also supports reduced waste in production processes. Procurement managers are encouraged to leverage the growing trend of single-sided EVA foam tape in their sourcing strategies. By partnering with innovative suppliers committed to quality and sustainability, businesses can ensure they remain competitive in their respective markets. As we advance toward 2025, embracing these cutting-edge adhesive solutions will be instrumental in driving operational efficiency and enhancing product reliability.

Single Sided Eva Foam Tape Dominates Winning in 2025

| Application | Material Thickness (mm) | Adhesion Strength (N/cm) | Temperature Resistance (°C) | Color Options |

|---|---|---|---|---|

| Automotive Interior | 1.0 | 15 | 80 | Black, Grey |

| Electronics | 0.5 | 10 | 70 | White, Black |

| Construction | 2.0 | 20 | 90 | Brown, Yellow |

| Furniture | 1.5 | 12 | 75 | Beige, Black |

| Packaging | 0.8 | 8 | 60 | Clear, White |

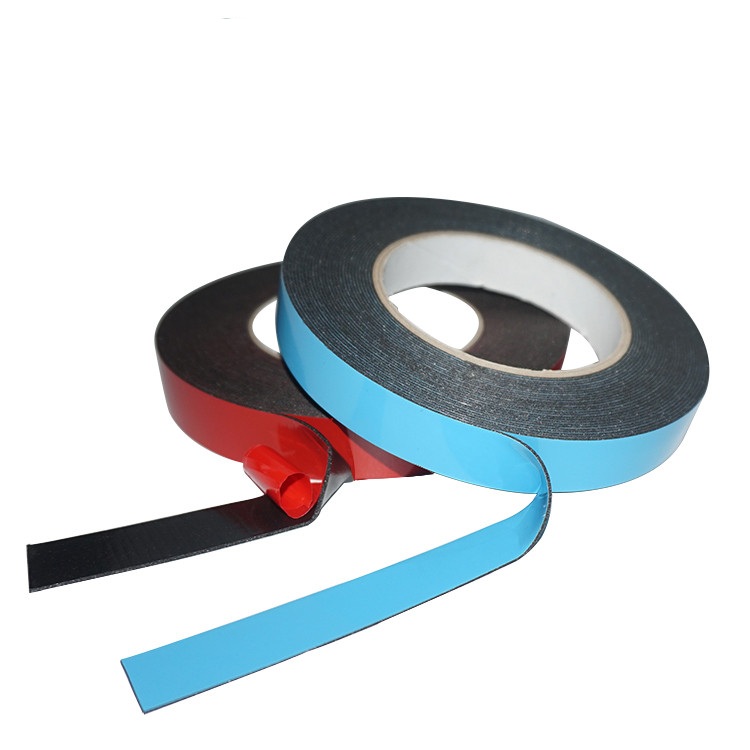

Related Products