China's Leading Manufacturer of Tape With Plastic: Quality & Innovation

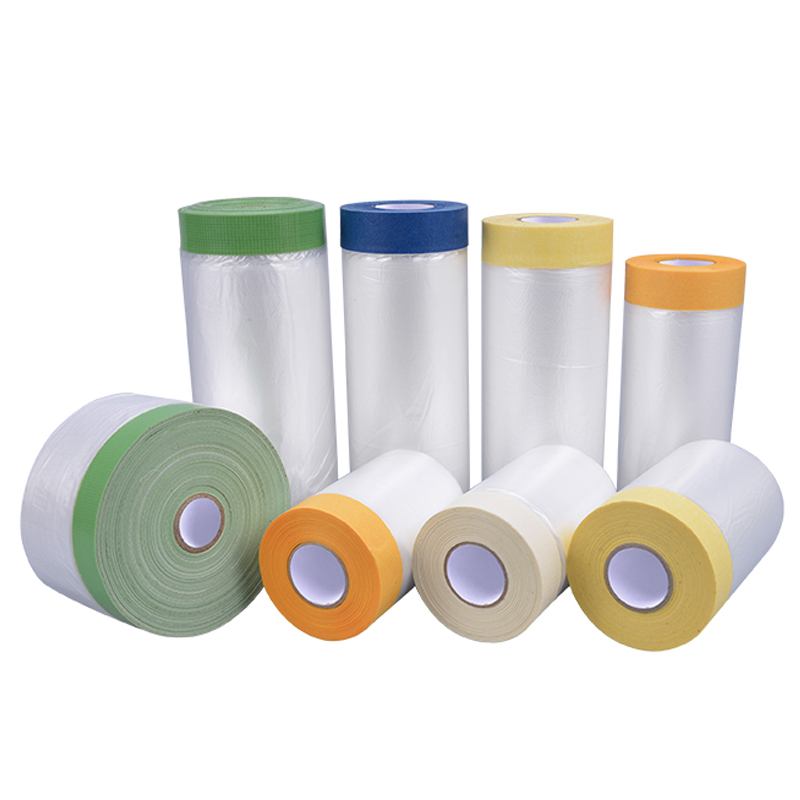

When I think about reliable adhesive solutions, Tape With Plastic really stands out to me. Sourced from a leading manufacturer in China, this tape combines durability and versatility perfect for various applications. Whether you're in packaging, construction, or crafting, I have found it to provide excellent adhesion and flexibility. The unique plastic backing ensures it withstands different conditions, making it great for both indoor and outdoor use. Why settle for less when you can choose a product that offers exceptional quality? Sourcing from a trusted manufacturer means you get consistent performance, and that’s crucial for any B2B operation. As someone who understands the importance of efficiency in procurement, I believe this tape will meet all your business needs without breaking the bank. Give it a try, and you won’t be disappointed!

Tape With Plastic Industry Giant From Concept to Delivery

In today’s fast-paced world, ensuring a seamless journey from concept to delivery is essential, particularly in the competitive landscape of the adhesive tape and plastic industries. Collaborating with a leading manufacturer offers global buyers access to innovative solutions tailored to meet diverse market needs. With an emphasis on high-quality materials and state-of-the-art production techniques, businesses can expect tapes that excel in performance, durability, and functionality. Effective partnership starts at the conceptual stage. By engaging with manufacturers early, buyers can benefit from expert insights that shape product specifications, ensuring that the final output aligns with their vision. The ability to rapidly prototype and iterate designs means that companies can bring their ideas to life without the common delays associated with traditional manufacturing processes. Furthermore, a robust supply chain fosters timely deliveries, allowing businesses to respond quickly to market demands and maintain their competitive edge. Ultimately, the journey from concept to delivery is about more than just producing tape; it’s about forging strong relationships that empower businesses to thrive. By leveraging the technical expertise and logistical capabilities of an established manufacturer, global buyers can focus on their core operations while confidently scaling their products in a dynamic marketplace. Such collaboration not only drives innovation but also guarantees that every product reaches its destination precisely as envisioned.

Tape With Plastic Industry Giant From Concept to Delivery

| Stage | Description | Duration | Stakeholders Involved | Deliverables |

|---|---|---|---|---|

| Concept Development | Identifying needs and ideas for the tape solution. | 2 weeks | Product Managers, Designers | Concept Proposal |

| Design Phase | Creating detailed designs and specifications. | 4 weeks | Engineers, Designers | Design Documents |

| Prototype Development | Building the initial prototype based on designs. | 3 weeks | Manufacturing Team, Engineers | Prototype Tape |

| Testing Phase | Conducting performance tests and adjustments. | 2 weeks | Quality Assurance, Engineers | Testing Report |

| Production | Full-scale manufacturing begins for the product. | 6 weeks | Production Team, Supply Chain | Final Tape Product |

| Delivery | Shipping products to customers and distributors. | 1 week | Logistics Team, Sales | Delivered Products |

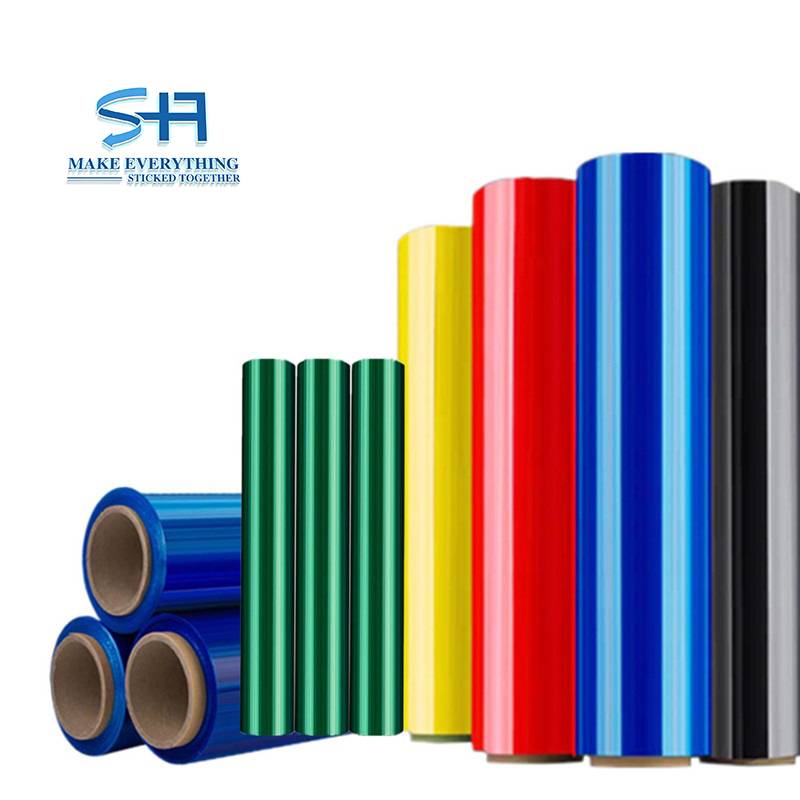

Related Products