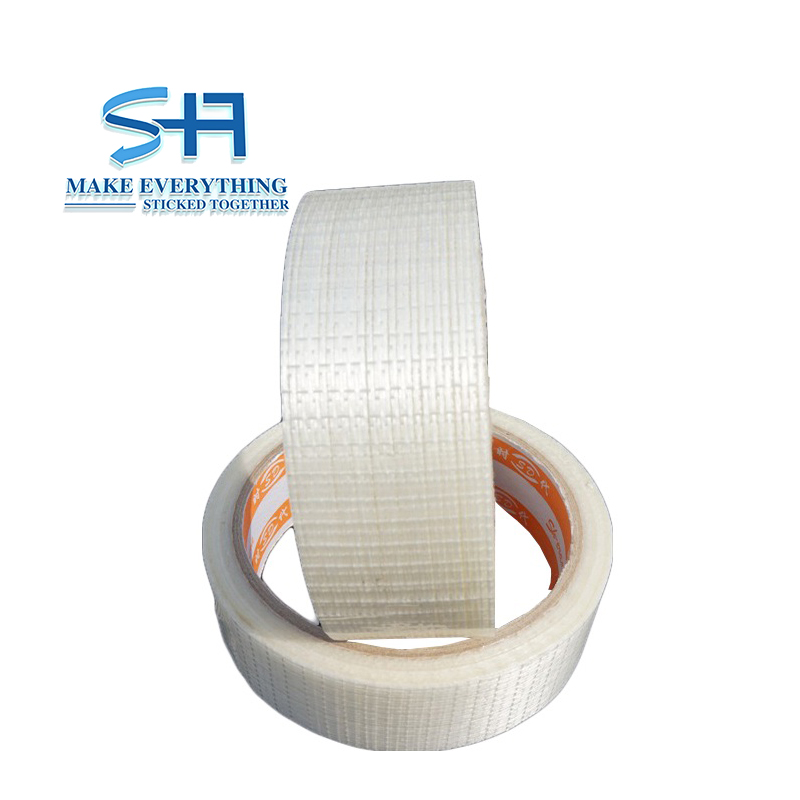

High-Quality Fiberglass Adhesive Tape from Trusted Suppliers

When it comes to reliable bonding solutions, I can’t recommend our high-quality fiberglass adhesive tape enough. This tape is designed to withstand extreme conditions while providing a strong and durable hold, making it ideal for various industrial applications. I’ve seen firsthand how it adheres seamlessly to different surfaces, ensuring that your projects stay secure and efficient. As a supplier dedicated to excellence, we take pride in sourcing only the best materials for our products. Our fiberglass adhesive tape is not just about sticking things together; it's about enhancing the overall quality and durability of your work. Whether you're in manufacturing, construction, or another sector, you’ll find our tape to be an invaluable asset. With our commitment to customer satisfaction, I’m confident you’ll appreciate the superior performance of our fiberglass adhesive tape. Let’s elevate your projects with a solution that truly delivers on quality and reliability.

Fiberglass Adhesive Tape in 2025 Ahead of the Curve

As we advance into 2025, the global market for fiberglass adhesive tape is poised for significant growth, driven by increasing demand across various industries such as automotive, construction, and electronics. Fiberglass adhesive tape is renowned for its high tensile strength, durability, and resistance to extreme temperatures and chemicals, making it an ideal choice for myriad applications. Companies looking to enhance their operational efficiency and product durability are now leveraging this innovative solution to meet stringent industry standards and consumer expectations. One of the key trends leading the fiberglass adhesive tape market is the shift towards sustainable materials and eco-friendly production processes. Manufacturers are increasingly focusing on developing adhesives that not only provide superior performance but also minimize environmental impact. This transition is not just a response to regulatory pressures but also reflects changing consumer preferences towards greener products. By utilizing advanced coatings and treatments, the latest fiberglass tapes exhibit improved adhesion properties and longevity, ensuring they can withstand both time and challenging conditions. For global buyers, investing in high-quality fiberglass adhesive tape means securing a competitive edge. The ability to source from dependable suppliers who prioritize innovation and sustainability can elevate product offerings and enhance brand reputation. As we navigate the ever-evolving landscape of material technology, aligning with a partner that stays ahead of the curve will enable businesses to meet the demands of modern applications while fostering sustainable practices for the future.

Fiberglass Adhesive Tape in 2025 Ahead of the Curve

| Application Area | Adhesive Type | Temperature Resistance (°C) | Thickness (mm) | Typical Uses |

|---|---|---|---|---|

| Electrical Insulation | Silicone-based | 150 | 0.15 | Wiring, transformers |

| Composite Repair | Epoxy-based | 200 | 0.30 | Aerospace, automotive |

| Thermal Insulation | Acrylic-based | 120 | 0.25 | HVAC systems |

| Sealing & Bonding | Rubber-based | 90 | 0.20 | Windows, doors |

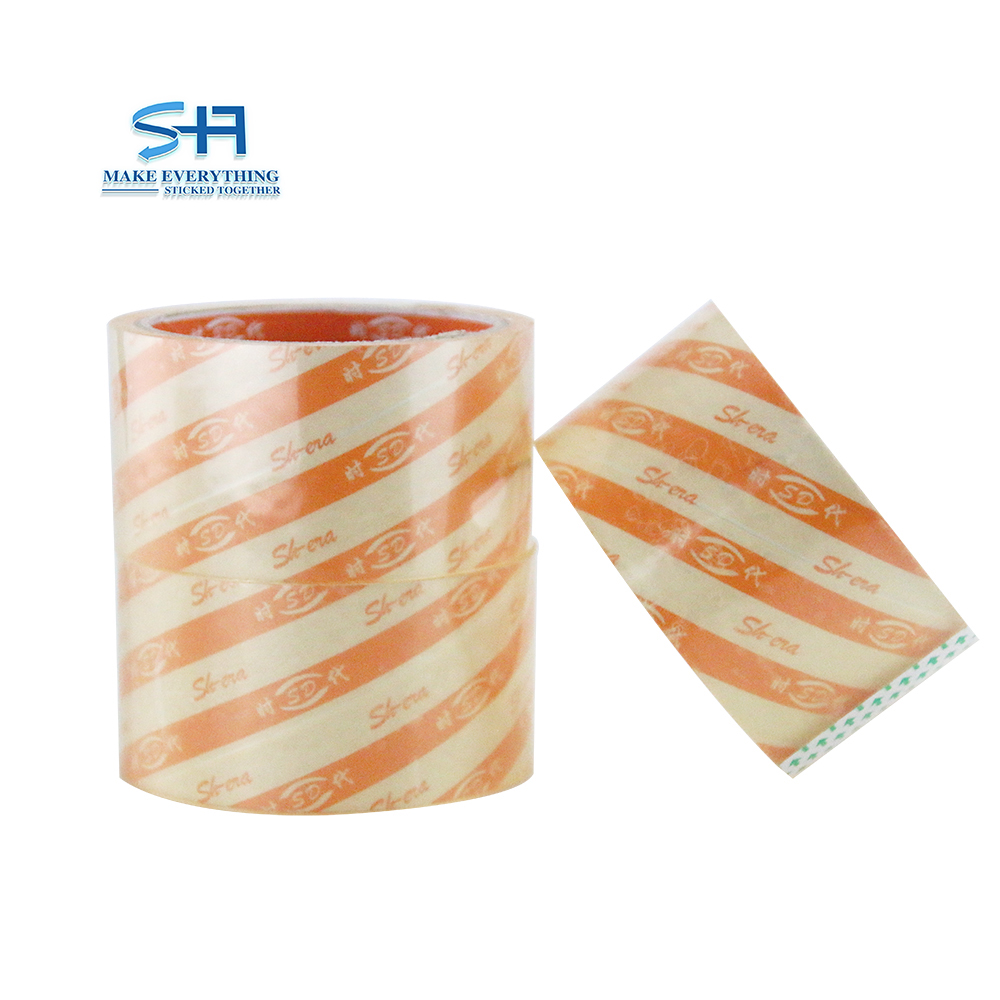

Related Products