PE Foam Strip: Get Quotes for Your Next Project Today!

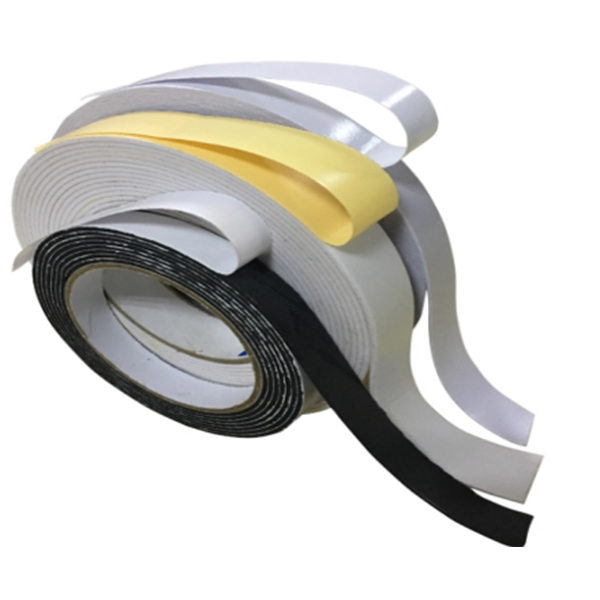

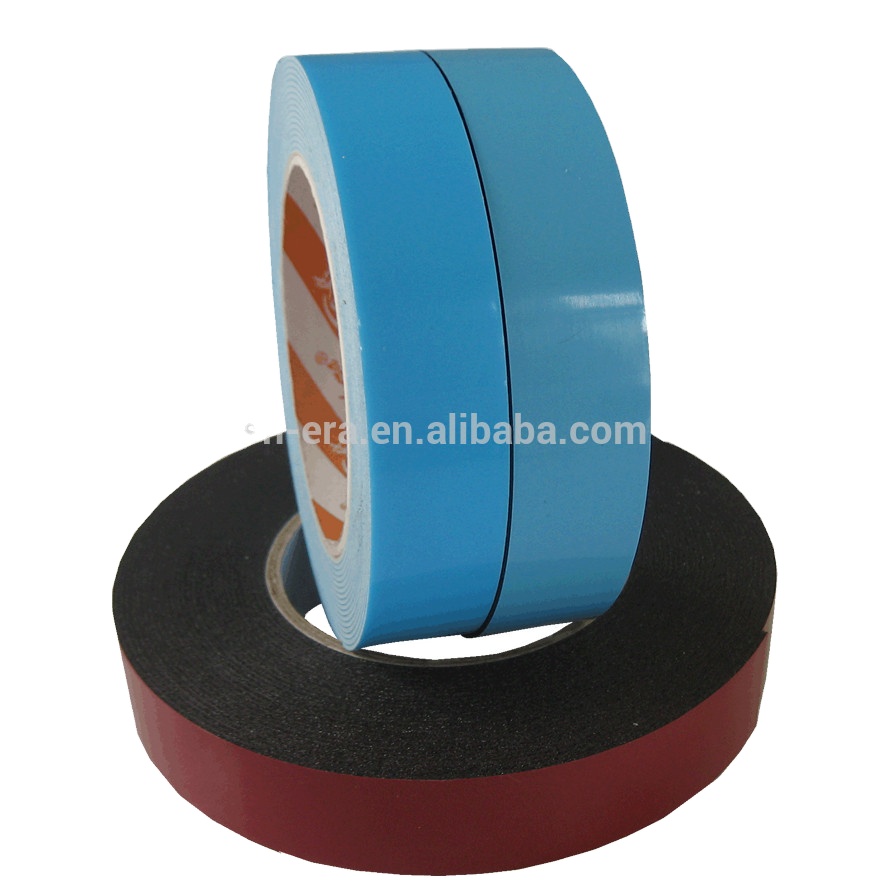

When I'm in need of reliable sealing solutions, {pe foam strips} always catch my attention. These flexible, lightweight strips provide excellent insulation and cushioning, making them ideal for a variety of applications. Whether for packaging, construction, or automotive needs, the versatility of these strips has proven invaluable for my projects. I often find myself exploring options to buy {pe foam strips} in bulk. The quotes I receive are competitive, ensuring I get the best deal without compromising on quality. It’s essential for me to choose a supplier who understands my requirements and provides prompt service. If you're navigating similar needs, I highly recommend considering {pe foam strips}. They’ve not only enhanced my projects but also streamlined my purchasing process. Reach out to get your quotes today, and let’s elevate the quality of our products together!

pe foam strip Manufacturer From Concept to Delivery

In today's competitive market, sourcing high-quality PE foam strips has never been more crucial for manufacturers and suppliers worldwide. From the initial concept to the final delivery, a systematic approach ensures that businesses receive products that meet their specific needs. The journey begins with comprehensive market research to understand the requirements of various industries, be it automotive, electronics, or construction. This meticulous planning phase lays the foundation for developing an advanced PE foam strip tailored to diverse applications. Once the concept is established, the focus shifts to production. Utilizing cutting-edge technology and innovative manufacturing techniques, businesses can ensure precision and quality control throughout the production process. Various factors, such as density, thickness, and adhesive strength, are meticulously engineered to create a product that not only meets but exceeds industry standards. This dedication to excellence guarantees that the PE foam strips are durable, reliable, and capable of providing the desired performance in real-world applications. As the final stage approaches, efficient logistics and distribution channels come into play. Timely delivery is paramount for global buyers, so investing in a streamlined supply chain ensures that products reach clients without delay. By partnering with a reliable manufacturer, procurement professionals can confidently source PE foam strips that align with their operational timelines and quality expectations. The journey from concept to delivery is a testament to the commitment to quality and customer satisfaction, making it easier for businesses worldwide to build durable and effective products.

PE Foam Strip Manufacturer From Concept to Delivery

| Stage | Description | Duration | Key Activities |

|---|---|---|---|

| Concept | Initial design and planning phase | 1-2 weeks | Research, brainstorming, sketching |

| Design | Creating detailed designs and specifications | 2-4 weeks | CAD modeling, material selection |

| Prototyping | Development of prototypes for testing | 3-6 weeks | Prototype manufacturing, testing |

| Production | Mass production of the foam strips | 4-8 weeks | Manufacturing, quality control |

| Delivery | Final delivery to the customers | 1-2 weeks | Packaging, shipping |

Related Products